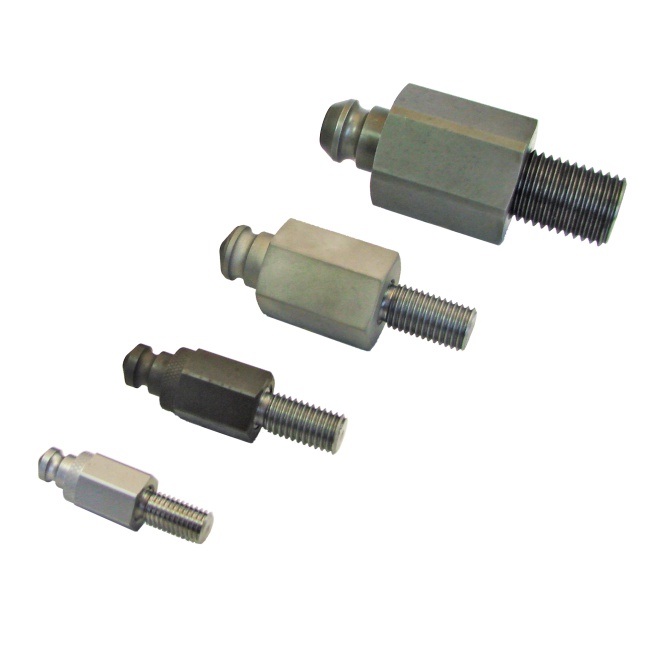

Smartflow Fastie Tool Studs

- Fastie Stud (Tool Side)

- 2.5 to 15 Tonnes Force

- Choice of Threads

£63.00 – £109.60 + Vat

Description

The FasTie Tool Stud is mounted on the mould tool of your moulding machine and used with Fastie couplers that may be permanently mounted to the ejector piston or press ejector plate. The quick-connect locking mechanism in the coupler snaps mechanically onto the mould-mounted pull stud during mould installation.

4 sizes are available: To fit 1″, 1-3/8″, 2″ and 3″ Fastie couplers.

![]()

Download: The Smartflow Fastie Brochure

- You will require a Fastie coupler.

- A centre air adaptor for single ejection systems

- A Fastie tool stud for location on your mould tool from this page.

Smartflow-Product-Summary-In-English.pdf

Smartflow Product Summary En français

Smartflow Product Summary Auf Deutsch

Smartflow Product Summary En Español

Smartflow Product Summary Po Polsku

For ejector plate systems you will require 2 or 4 coupler and 1 or 4 tool studs, a centre air adaptor is not required as the air supply can be connected directly to the back of the Fastie coupler through the back of the ejector plate.

To release the knockouts, apply shop air to the coupler.

The coupler opens to release the pull stud, disconnecting the press and mould ejector plates. The coupler remains in the open position, ready for a new mould to be set.

For central single ejector systems you will require a centre air adaptor which allows pneumatic air to reach the back of the coupler to supply the required air for opening the coupler.

For multiple knockout locations, an air manifold is recommended to release all couplers simultaneously.

The FasTie couplers and pull studs are available in 4 sizes to suit various press sizes: 1″, 1-3/8″, 2″ and 3″.

Mounting accessories such as centre adapters and knockout bars are available to facilitate installation without additional machining to presses or injection moulds.

Moulding Machine Requirements

| Coupler Size | 1 inch | 1-3/8 inch | 2 inch | 3 Inch |

|---|---|---|---|---|

| Platen thru hole min. | 27mm | 36.8mm | 52.4mm | 77.8mm |

| Ejector plate thru hole min. | 14mm | 16.5mm | 19.4mm | 25.8mm |

| Ejector force per coupler max. | 2.5 Tonne | 5.5 Tonne | 7.5 Tonne | 15 Tonne |

Guide for choosing correct size Fastie

| Press Tonnage | 1 (Centre Ejector) | 2 Plate Ejector | 4 Plate Ejector |

|---|---|---|---|

| 0 - 250 | 1" | 1" | 1" |

| 250 - 500 | 1-3/8" | 1" or 1-3/8" | 1" or 1-3/8" |

| 500 - 750 | 2" | 1-3/8" or 2" | 1-3/8" or 2" |

| 750 - 1000 | 2" | 1-3/8" or 2" | 1-3/8" or 2" |

| 1000+ | - | 2" or 3" | 2" or 3" |

Why Buy?

- FasTie installs easily with central ejector systems (with centre air adaptor) and into existing tapped holes, no additional machining is required.

- FasTie reduces mould setting time by quickly uncoupling without loose parts to stow.

- FasTie remains coupled during mould cycling for increased “tie-in” reliability and reduced wear.

- SpeedBar® adjustable knockout bar changes length quickly without tools [±1/2″(12.7mm) from nominal in .006″(.15mm) increments].(1″ Models Only)

- SpeedBar saves moulders time and cost of machining individual knockout bars to fit different moulds.